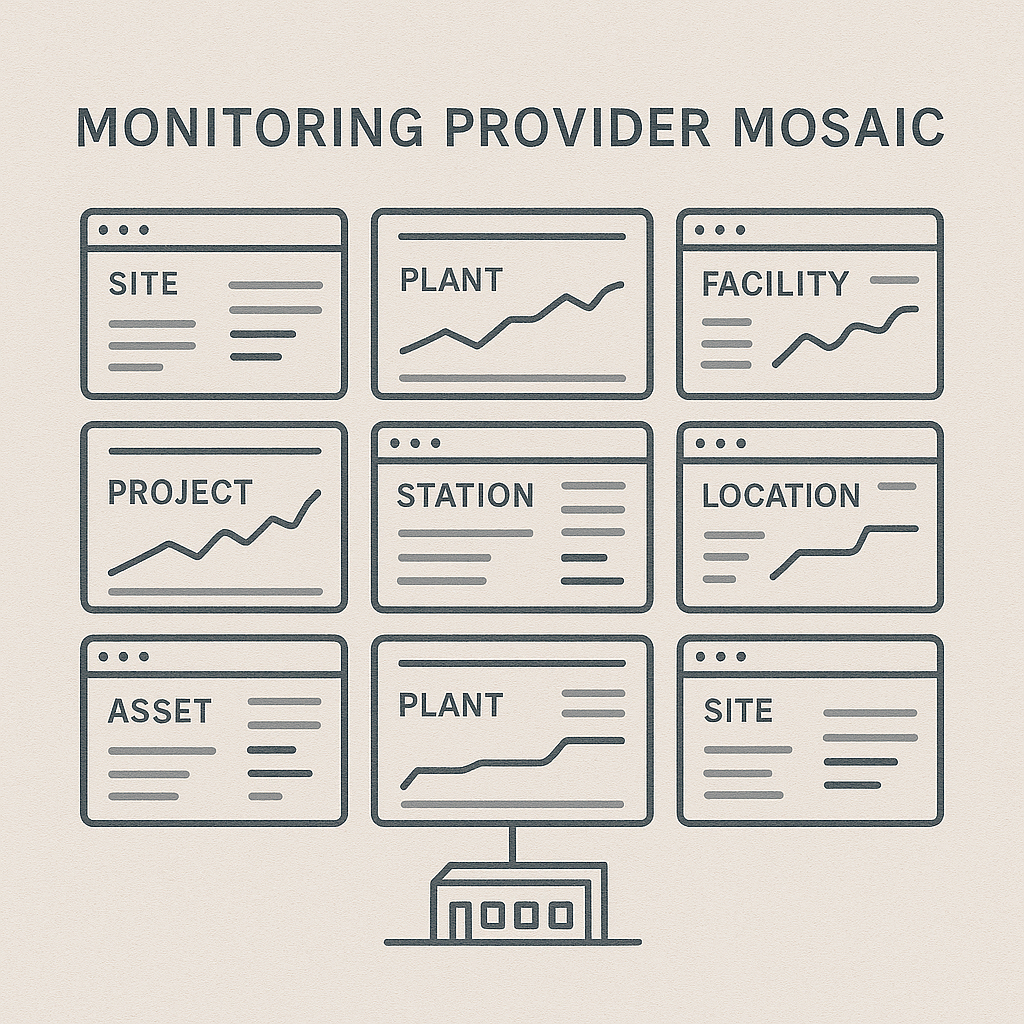

The Hidden Costs of PV Data Fragmentation Across Monitoring Providers

Most operators think fragmentation is an inconvenience. In reality, it's one of the largest hidden operational costs in solar portfolios.

Fragmentation isn't only about having multiple logins. It's about:

- different metadata models

- mismatched naming conventions

- inconsistent capacity fields

- incompatible inverter numbering

- differing file formats

- varied assumptions in KPI calculations

This fragmentation becomes structural overhead. And that overhead compounds as portfolios grow.

This topic connects directly with Multi-Monitoring Complexity.

Why Fragmentation Matters More Than Most Teams Realize

At first, multiple systems seem manageable. But under the surface, fragmentation impacts:

1. Normalization

AC capacity in one system isn't AC capacity in another. Nominal power fields differ. Correction factors vary.

2. Naming conventions

One provider uses "INV03," another "3_Inv," another "Inverter-West-3."

3. KPI definitions

Even simple metrics like PR differ across portals.

4. Metadata completeness

Some portals include string-level details. Others provide barely anything.

5. Export structures

CSV, XLSX, TSV, JSON, API variations - all different.

The result is operational friction. Every analysis starts by reconstructing context.

How Fragmentation Creates Hidden Costs

1. Manual cross-system alignment

Analysts manually map:

- inverter lists

- transformer allocations

- MPPT structures

- capacity fields

- naming conventions

Hours disappear before analysis even begins.

2. Divergent truths emerge

Correction made in one system never reaches the others. Teams unknowingly operate with conflicting assumptions.

3. Investigations slow down

Each incident requires cross-checking:

- monitoring portal

- OEM interface

- SCADA exports

- spreadsheets

- historical screenshots

See: Why Solar Performance Investigations Take Longer Than They Should (coming soon).

4. KPI drift is amplified

Drift becomes harder to detect when KPIs differ by provider.

See: KPI Drift in Solar Assets: The Silent Risk No Monitoring System Warns You About.

The Portfolio-Scale Effect

The larger the portfolio, the more monitoring systems appear:

- Portal 1 for the legacy sites

- Portal 2 for EPC A

- Portal 3 for EPC B

- Portal 4 for repowered sites

- OEM-level tools for certain inverters

Each new site introduces variation. Each variation introduces alignment work.

This compounds into:

- slower reporting cycles

- inconsistent executive summaries

- higher overhead for audits

- less trust in analytics across teams

What Operators Can Do Today

1. Maintain a unified naming scheme

Even if the systems differ, your internal naming can stay consistent.

2. Normalize capacity fields across providers

Create a single definition for DC and AC capacity and enforce it.

3. Track system-specific quirks

Keep a record of each monitoring provider's metadata limitations.

4. Reconcile corrections centrally

When something is fixed in one system, reflect it elsewhere.

See also

- Multi-Monitoring Complexity (coming soon)

- Technical Information Consistency (coming soon)

- KPI Drift in Solar Assets: The Silent Risk No Monitoring System Warns You About