How Portfolio Growth Exposes Hidden Weaknesses in Solar Data Management

Solar portfolios are stable when they're small. Teams know the plants. Documents are recent. Naming conventions hold together through discipline, not structure.

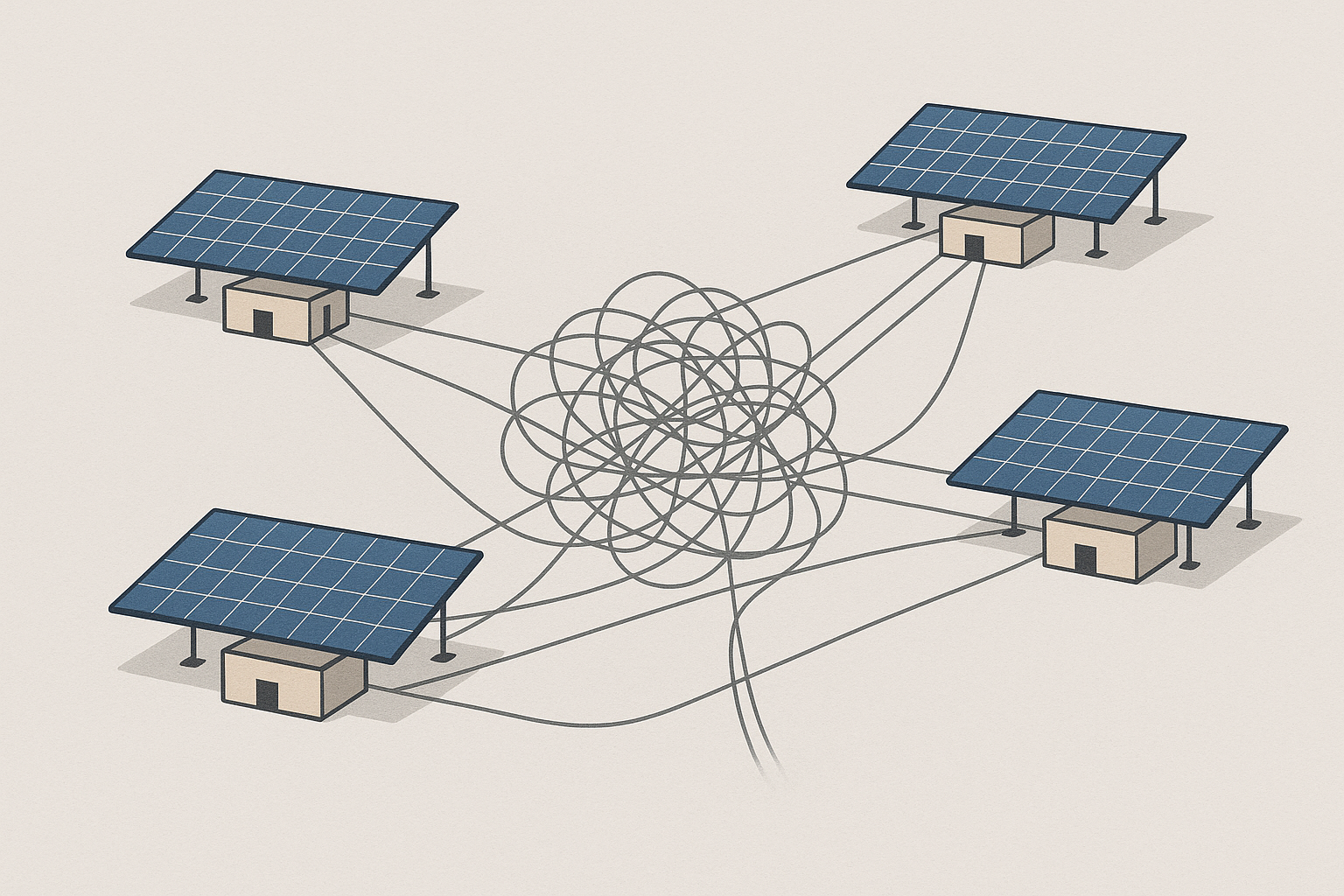

Growth changes everything.

As soon as a portfolio expands, hidden weaknesses emerge: inconsistent metadata, undocumented equipment changes, capacity mismatches, and workflows that depend on tribal knowledge.

These weaknesses don't appear because teams make mistakes. They appear because scaling reveals everything that was never formalized.

Growth Amplifies the Gaps

When a portfolio doubles, three things happen:

1. Tribal knowledge stops scaling

Operators who once held everything in their heads now manage plants they've never visited.

2. Documentation patterns diverge

Each EPC, monitoring provider, and service partner introduces a different structure for:

- inverter naming

- string counts

- MPPT topology

- transformer groupings

- plant capacity descriptions

These inconsistencies are the seed of future drift.

3. Monitoring platforms reveal their limits

Monitoring systems were never designed to unify technical metadata across hundreds of sites. They surface performance-not configuration truth.

See: Why Monitoring Systems Can't Track Everything (coming soon)

The Compounding Effect: Small Inconsistencies Become Systemic

What starts as minor variations eventually become operational friction:

- one plant reports AC capacity, another DC

- naming conventions differ by EPC

- one inverter replacement is documented, the next is not

- string realignments are captured in email threads, not metadata

These issues never stay local. They compound as portfolios grow and teams change.

This is the same pattern explored in The Silent Spread of Inconsistent Technical Information (coming soon).

Portfolio Growth Reveals Three "Structural Gaps"

Gap 1: Inconsistent Technical Foundations

Metadata forms the base for:

- KPIs

- benchmarking

- capacity-normalized comparisons

- alarms

- transformer-level aggregation

When that foundation varies plant to plant, analytics become fragile.

Gap 2: Lack of Change Tracking

Growth increases:

- inverter swaps

- module replacements

- repowering

- topology changes

- communications upgrades

- device firmware updates

Without structured tracking, these changes introduce silent KPI drift.

See: KPI Drift in Solar Assets

Gap 3: More Vendors, More Models, More Variations

Every new site adds variation. Every variation adds overhead.

This dynamic is explored deeper in Multi-Monitoring Complexity (coming soon).

How These Weaknesses Impact Operations

1. longer investigations

Analysts spend hours reconstructing context.

2. inconsistent reporting

KPIs drift because capacity, naming, or topology data isn't aligned.

3. unreliable benchmarking

Plants appear to over- or under-perform simply because the metadata model differs.

4. onboarding strain

New team members cannot reconstruct the undocumented history.

5. portfolio-level instability

More plants introduce more divergence. More divergence introduces more manual correction.

What Operators Can Do Today

You don't need full digitalization to improve reliability. Start with small structural habits:

1. Normalize naming conventions portfolio-wide

2. Track all equipment changes as soon as they occur

3. Capture DC and AC capacity consistently

4. Define a clear baseline for each plant

This prevents KPI drift caused by silent configuration shifts.