Why Monitoring Systems Can't Track Everything and Shouldn't

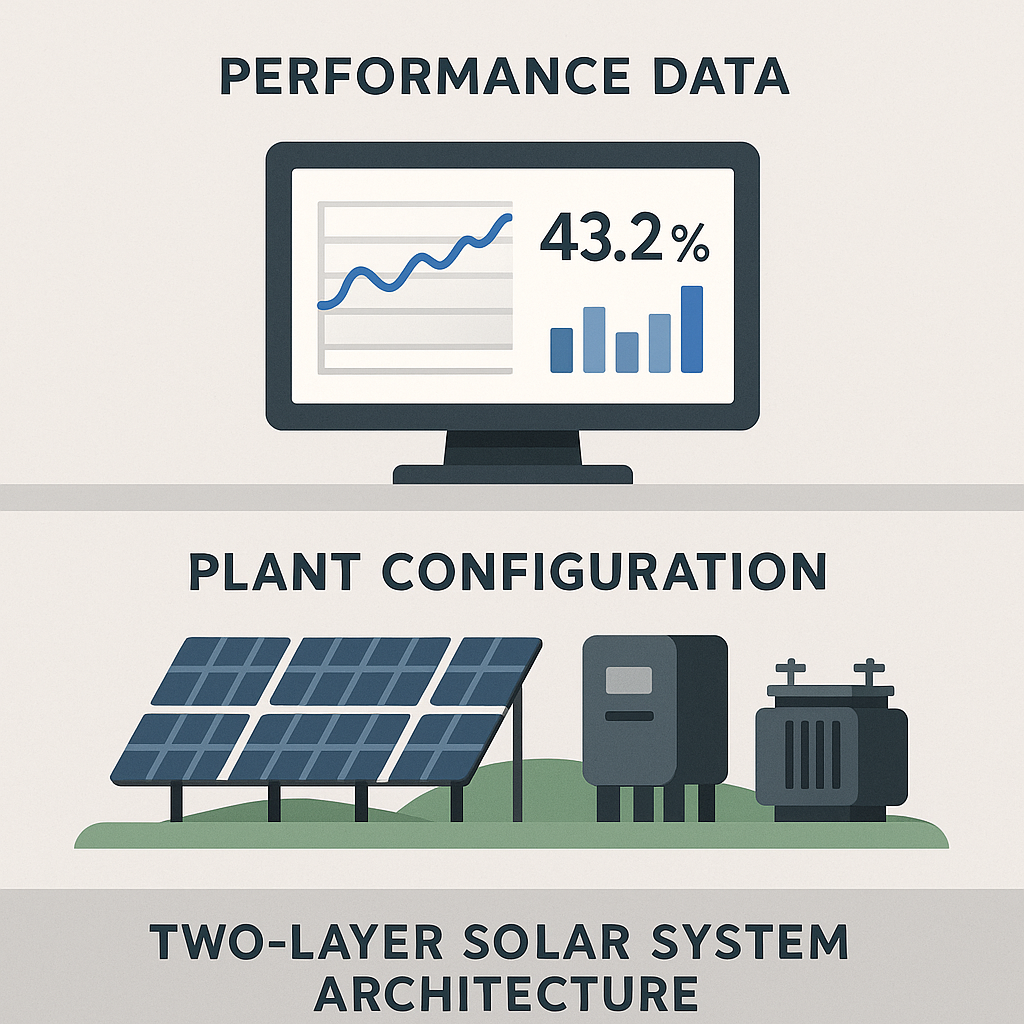

Monitoring platforms are excellent at what they're designed to do: collect performance data, detect anomalies, and visualize production trends, focus on now.

What they are not designed to do is maintain the evolving technical truth of a plant.

Expecting them to do both leads to misaligned assumptions, incomplete change histories, and silent KPI drift.

This topic connects directly with KPI Drift in Solar Assets: The Silent Risk No Monitoring System Warns You About and Why Digitalization in Solar Often Fails Before It Even Starts.

What Monitoring Systems Are Designed For

Monitoring systems specialize in:

- high-frequency performance data

- alarms

- PR and basic KPI calculations

- communication status

- real-time dashboards

- availability metrics

- event logs

They capture what happened.

They do not capture what changed in the plant that explains what happened.

What They Can't Track Reliably

1. Configuration history

No monitoring platform maintains a detailed historical record of:

- string realignments

- inverter replacements

- module swaps

- MPPT topology adjustments

- repowering decisions

- transformer re-groupings

Without this context, baselines drift silently.

See KPI Drift in Solar Assets: The Silent Risk No Monitoring System Warns You About.

2. Naming consistency

Names entered during commissioning tend to remain forever, even if:

- topology changes

- inverters are swapped

- string allocations change

- new EPCs introduce new conventions

3. Capacity corrections

Capacities in portals often depend on:

- manual entry

- template defaults

- outdated EPC information

4. Component mapping

Monitoring providers rarely maintain:

- module serial lists

- combiner box mappings

- MPPT-to-string allocations

5. EPC-level documentation

Monitoring portals do not manage the broader documentation set.

Why Monitoring Systems Shouldn't Track Everything

Trying to make monitoring systems the "single source of truth" for both performance and configuration creates structural problems:

1. They are not designed for configuration lifecycle management

Configuration truth changes frequently. Portals are optimized for data ingestion, not documentation.

2. They lack the granularity to model physical layouts

Understanding physical arrangement is outside their scope.

3. They don't version metadata

Even when metadata exists, it rarely has timestamps or change logs.

4. They assume stable plant models

Most internal algorithms assume comparatively static configurations.

Digitalization fails when built on this assumption. See Why Digitalization in Solar Often Fails Before It Even Starts.

What Operators Should Expect from Monitoring Providers

Monitoring providers excel at:

- data accuracy

- stable time-series

- solid alarm logic

- communication management

- standard KPIs

- visualization

They are not:

- metadata custodians

- configuration historians

- change tracking systems

This division of responsibility is healthy.

What Operators Can Do Today

1. Treat performance and configuration as separate layers

Each deserves its own structure.

2. Maintain independent configuration tracking

A minimal system capturing:

- capacities

- topology

- changes over time

3. Reconcile portal metadata regularly

A simple periodic review prevents major inconsistencies.

- Don't overload monitoring platforms

Let them excel at what they do best.